Asset remote monitoring sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. It’s a world where technology empowers businesses to manage their assets with unprecedented efficiency and foresight.

Table of Contents

Asset remote monitoring, also known as remote asset monitoring, is a powerful tool that enables businesses to track and manage their assets from anywhere in the world. It involves collecting data from sensors and other devices attached to assets, transmitting that data to a central location, and then using that data to make informed decisions about asset maintenance, performance, and utilization. The benefits of asset remote monitoring are far-reaching, impacting everything from cost savings to improved safety and environmental sustainability.

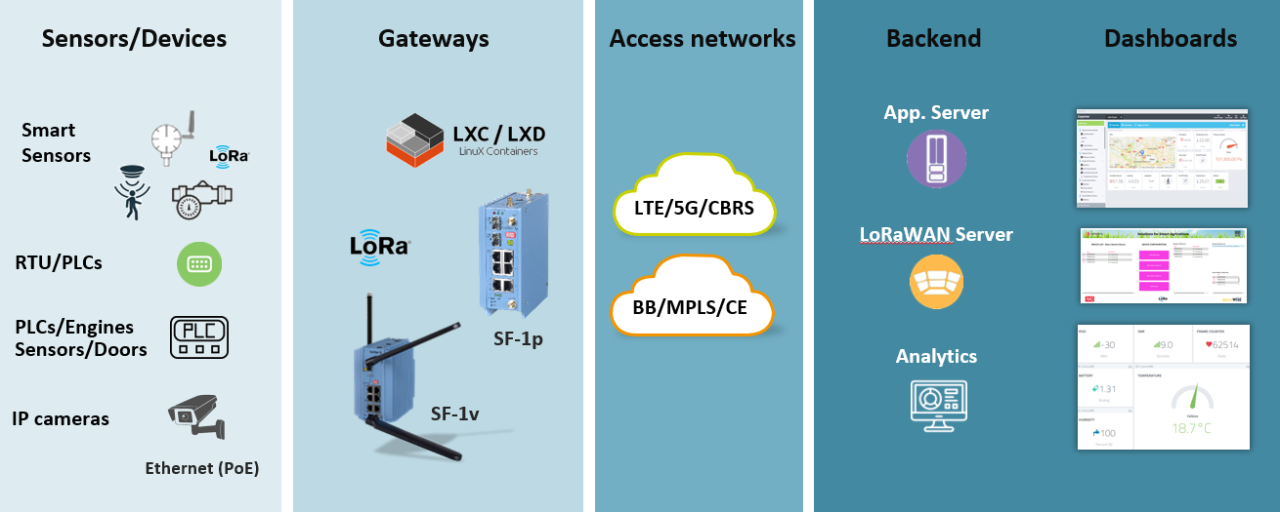

Components of an Asset Remote Monitoring System

An asset remote monitoring system is a comprehensive solution that enables businesses to track and manage their assets in real-time, regardless of their physical location. It involves a combination of hardware, software, and communication protocols to gather data, analyze it, and provide actionable insights. This information helps businesses optimize asset performance, reduce downtime, improve maintenance schedules, and make informed decisions.

Hardware Components

Hardware components form the foundation of an asset remote monitoring system. They are responsible for collecting data from assets and transmitting it to the software platform for analysis and visualization.

- Sensors: Sensors are the primary data collection devices. They are deployed on assets to measure various parameters such as temperature, pressure, vibration, humidity, and flow. Common types of sensors include temperature sensors, pressure sensors, vibration sensors, and flow sensors.

- Data Loggers: Data loggers are devices that store sensor readings and transmit them to the software platform. They can be standalone devices or integrated into larger systems. Data loggers typically have memory for storing data, communication interfaces for transmitting data, and software for managing data collection and transmission.

- Gateways: Gateways act as intermediaries between sensors and the software platform. They receive data from sensors, convert it into a compatible format, and transmit it to the software platform over a network connection. Gateways can be wired or wireless, depending on the specific needs of the system.

- Communication Devices: Communication devices facilitate the transmission of data between sensors, data loggers, gateways, and the software platform. Common communication technologies include cellular networks, Wi-Fi, Bluetooth, and satellite communication. The choice of communication technology depends on factors such as coverage area, data transmission speed, and cost.

Software Platforms

Software platforms are the brains behind asset remote monitoring systems. They collect data from hardware components, analyze it, and present it in a user-friendly format.

- Data Acquisition and Storage: Software platforms collect data from hardware components through communication protocols. This data is then stored in databases for historical analysis and reporting.

- Data Analysis and Visualization: Software platforms perform various types of data analysis, such as trend analysis, anomaly detection, and predictive maintenance. The results of these analyses are presented in dashboards and reports for easy interpretation and decision-making.

- Alerting and Notifications: Software platforms can trigger alerts and notifications based on predefined thresholds or conditions. This allows operators to be informed of potential issues or anomalies in real-time, enabling prompt action.

- Remote Control and Management: Some software platforms offer remote control and management capabilities, allowing operators to adjust settings, update firmware, and manage assets from a central location.

Communication Protocols

Communication protocols are essential for enabling data exchange between different components of an asset remote monitoring system. They define the rules and standards for data transmission, ensuring compatibility and seamless integration.

- Modbus: Modbus is a widely used communication protocol for industrial automation. It is a serial communication protocol that allows devices to exchange data over a network connection. Modbus is often used in asset remote monitoring systems to communicate with sensors, data loggers, and gateways.

- MQTT: MQTT (Message Queuing Telemetry Transport) is a lightweight, publish-subscribe protocol designed for constrained devices and low-bandwidth networks. It is commonly used in IoT applications, including asset remote monitoring, for its efficiency and scalability.

- OPC UA: OPC UA (Open Platform Communications Unified Architecture) is a communication protocol that provides a standardized way for devices and systems to exchange data. It is widely used in industrial automation and is becoming increasingly popular in asset remote monitoring systems.

Asset Management and Maintenance

Asset remote monitoring data is invaluable for optimizing asset management strategies. It provides real-time insights into asset health, performance, and operational efficiency, enabling proactive maintenance and minimizing downtime.

Role of Remote Monitoring in Proactive Maintenance

Remote monitoring plays a crucial role in proactive maintenance, allowing for early detection of potential issues before they escalate into major problems. By continuously tracking asset performance parameters, such as temperature, vibration, pressure, and power consumption, maintenance teams can identify anomalies and address them promptly. This approach helps prevent unexpected failures, reduce maintenance costs, and extend asset lifespan.

Benefits of Integrating Asset Remote Monitoring with Existing Maintenance Systems

Integrating asset remote monitoring with existing maintenance systems offers significant advantages. It streamlines maintenance processes, enhances communication, and provides a comprehensive view of asset health and performance.

- Improved Maintenance Planning: Remote monitoring data provides valuable insights into asset usage patterns and wear and tear, enabling maintenance teams to plan preventive maintenance schedules more effectively. This helps ensure that maintenance is performed at optimal intervals, reducing the risk of unexpected failures and minimizing downtime.

- Enhanced Asset Visibility: Remote monitoring systems provide real-time visibility into asset health and performance, enabling maintenance teams to track asset conditions remotely. This allows for faster response times to potential issues, reducing the impact of downtime and improving overall asset availability.

- Optimized Maintenance Resources: By identifying potential issues early, remote monitoring helps optimize maintenance resource allocation. This prevents unnecessary maintenance interventions and ensures that maintenance resources are deployed effectively, reducing costs and improving operational efficiency.

Applications of Asset Remote Monitoring

Asset remote monitoring has become an indispensable tool for optimizing operations and maximizing asset performance across various industries. This technology offers real-time insights into asset health, enabling proactive maintenance, reducing downtime, and improving overall efficiency.

Asset Remote Monitoring in the Oil and Gas Industry

Remote monitoring systems play a crucial role in ensuring the safety and efficiency of oil and gas operations. By continuously monitoring critical equipment such as pipelines, pumps, and compressors, operators can detect potential issues early on, preventing costly breakdowns and environmental hazards.

- Predictive Maintenance: Remote monitoring systems collect data on vibration, temperature, pressure, and other parameters, enabling predictive maintenance strategies. This allows operators to schedule maintenance before failures occur, minimizing downtime and reducing maintenance costs.

- Leak Detection: Remote monitoring systems can detect leaks in pipelines and other equipment, preventing environmental damage and ensuring regulatory compliance. Acoustic sensors, for example, can identify leaks by detecting unusual noise patterns.

- Remote Control and Automation: Remote monitoring systems allow operators to control and automate critical equipment remotely, reducing the need for on-site personnel and improving safety. This is particularly beneficial in remote or hazardous environments.

Asset Remote Monitoring in Manufacturing

In manufacturing, asset remote monitoring is essential for optimizing production processes, minimizing downtime, and improving overall efficiency. By monitoring equipment performance and identifying potential issues, manufacturers can ensure continuous production and reduce costs.

- Production Optimization: Remote monitoring systems provide real-time data on machine performance, allowing manufacturers to optimize production processes and increase throughput. By identifying bottlenecks and inefficiencies, manufacturers can adjust operations to improve overall efficiency.

- Preventive Maintenance: Remote monitoring systems enable proactive maintenance by detecting potential issues before they lead to failures. This minimizes downtime, reduces repair costs, and ensures continuous production.

- Quality Control: Remote monitoring systems can track and monitor product quality parameters, ensuring consistency and meeting customer expectations. This can include monitoring temperature, pressure, and other factors that affect product quality.

Asset Remote Monitoring in Transportation

The transportation industry relies heavily on asset remote monitoring to ensure safety, efficiency, and compliance. By monitoring vehicles and infrastructure, operators can optimize routes, reduce fuel consumption, and enhance safety.

- Fleet Management: Remote monitoring systems provide real-time data on vehicle location, speed, fuel consumption, and other parameters, enabling efficient fleet management. This allows operators to optimize routes, reduce fuel costs, and improve driver safety.

- Predictive Maintenance: Remote monitoring systems can detect potential issues with vehicles, such as engine problems or tire wear, allowing for proactive maintenance and minimizing downtime.

- Safety and Security: Remote monitoring systems can track vehicle movements, monitor driver behavior, and detect potential safety hazards, improving overall safety and security.

Case Studies

Case Study 1: Oil and Gas Company Improves Efficiency and Reduces Downtime

A major oil and gas company implemented a remote monitoring system for its offshore drilling platform. The system monitored critical equipment such as pumps, compressors, and generators, providing real-time data on their performance. The company was able to identify potential issues early on, preventing costly breakdowns and reducing downtime. As a result, the company saw a significant increase in production efficiency and a reduction in maintenance costs.

Case Study 2: Manufacturing Company Optimizes Production Processes and Improves Quality

A manufacturing company implemented a remote monitoring system for its production line. The system monitored machine performance, production output, and product quality parameters. The company was able to identify bottlenecks in the production process and adjust operations to improve efficiency. The system also helped the company to identify and address quality issues early on, ensuring product consistency and meeting customer expectations.

Case Study 3: Transportation Company Reduces Fuel Consumption and Improves Safety

A transportation company implemented a remote monitoring system for its fleet of trucks. The system provided real-time data on vehicle location, speed, and fuel consumption. The company was able to optimize routes, reduce fuel consumption, and improve driver safety. The system also allowed the company to monitor driver behavior and identify potential safety hazards, leading to a significant reduction in accidents.

Future Trends in Asset Remote Monitoring

Asset remote monitoring is rapidly evolving, driven by advancements in technology, particularly in the realms of artificial intelligence (AI) and the Internet of Things (IoT). These innovations are poised to revolutionize how assets are managed, maintained, and optimized, ushering in a new era of efficiency and predictive capabilities.

Impact of AI and IoT on Asset Remote Monitoring

The integration of AI and IoT into asset remote monitoring systems is transforming the landscape, offering unprecedented levels of intelligence and automation. AI algorithms can analyze vast amounts of data collected from sensors and other sources, identifying patterns and anomalies that may indicate potential problems. This proactive approach enables predictive maintenance, allowing for timely interventions before failures occur, minimizing downtime and extending asset lifecycles.

IoT devices, with their ability to connect and communicate with each other, provide real-time insights into asset performance, location, and environmental conditions. This constant stream of data empowers operators to make informed decisions, optimize asset utilization, and improve overall operational efficiency.

Potential Impact of Emerging Technologies on Asset Management

The convergence of AI and IoT is shaping the future of asset management in several key ways:

- Enhanced Predictive Maintenance: AI-powered analytics can predict potential failures based on historical data, sensor readings, and environmental factors. This enables proactive maintenance strategies, reducing downtime and extending asset lifecycles. For example, a wind turbine manufacturer could leverage AI to analyze vibration data and predict when a bearing might fail, allowing for timely replacement before it causes a major outage.

- Improved Asset Utilization: IoT sensors can track asset usage and performance in real-time, enabling operators to optimize utilization and minimize idle time. For instance, a fleet management company could use IoT sensors to monitor vehicle location and usage, optimizing routes and schedules to maximize efficiency.

- Real-Time Asset Tracking: IoT devices can provide real-time location tracking, enabling efficient asset management and inventory control. This is particularly valuable for high-value assets or those operating in remote locations, where visibility is crucial.

- Automated Decision-Making: AI algorithms can automate decision-making processes, reducing human error and improving efficiency. For instance, AI-powered systems can automatically adjust operating parameters based on real-time data, optimizing asset performance and reducing energy consumption.

Challenges and Opportunities Associated with Emerging Technologies

While AI and IoT offer significant potential, their implementation in asset remote monitoring also presents challenges and opportunities:

- Data Security and Privacy: The increasing reliance on data raises concerns about security and privacy. Robust security measures are essential to protect sensitive asset data from unauthorized access or cyberattacks.

- Data Management and Analytics: Managing and analyzing vast amounts of data generated by IoT devices requires sophisticated infrastructure and expertise. Organizations need to invest in data management solutions and develop analytical capabilities to extract meaningful insights.

- Integration and Compatibility: Integrating AI and IoT systems with existing asset management infrastructure can be complex and require careful planning. Ensuring compatibility between different devices and systems is crucial for seamless operation.

- Skill Development: Implementing and managing AI and IoT-powered asset remote monitoring systems requires a skilled workforce with expertise in these technologies. Organizations need to invest in training and development programs to equip their employees with the necessary skills.

Security Considerations in Asset Remote Monitoring

The increasing reliance on remote asset monitoring systems introduces significant security vulnerabilities and risks. These systems collect and transmit sensitive data about assets, making them attractive targets for cyberattacks. Robust security measures are crucial to protect data integrity, ensure system reliability, and maintain operational continuity.

Data Security and Privacy

Protecting sensitive data transmitted through remote monitoring systems is paramount. This involves implementing measures to prevent unauthorized access, data breaches, and misuse of information.

- Data Encryption: Encrypting data in transit and at rest using strong encryption algorithms like AES-256 is essential. This prevents unauthorized access even if data is intercepted.

- Secure Communication Protocols: Using secure protocols like HTTPS, TLS, and VPNs for data transmission ensures confidentiality and integrity.

- Access Control: Implementing multi-factor authentication and role-based access control restricts access to authorized personnel, preventing unauthorized users from accessing sensitive data.

- Data Masking and Tokenization: Replacing sensitive data with non-sensitive tokens or masks reduces the risk of data breaches.

- Regular Security Audits: Conducting regular security audits helps identify vulnerabilities and implement necessary security controls.

System Security and Integrity, Asset remote monitoring

Securing the remote monitoring system itself is equally important to prevent malicious actors from compromising its functionality.

- Firewall Protection: Implementing a robust firewall to filter out unauthorized traffic and protect the system from external attacks is essential.

- Intrusion Detection and Prevention Systems (IDS/IPS): Deploying IDS/IPS helps detect and prevent malicious activity by monitoring network traffic for suspicious patterns.

- Regular Software Updates: Keeping system software and firmware up to date with the latest security patches is crucial to address vulnerabilities and prevent exploits.

- Secure Network Segmentation: Isolating the remote monitoring system from other network segments reduces the risk of lateral movement by attackers.

- Redundancy and Backup: Implementing redundancy and backups ensures system availability even in the event of a security breach or failure.

Security Best Practices

Adopting best practices for security can significantly reduce the risk of attacks and ensure the integrity of the remote monitoring system.

- Employee Training: Educating employees on cybersecurity best practices, such as strong password hygiene and recognizing phishing attempts, is crucial to prevent human error.

- Incident Response Plan: Having a well-defined incident response plan helps organizations quickly identify, contain, and mitigate security incidents.

- Regular Security Assessments: Performing regular security assessments by independent security experts helps identify vulnerabilities and potential risks.

- Compliance with Security Standards: Adhering to relevant security standards like ISO 27001, NIST Cybersecurity Framework, and GDPR helps ensure data security and privacy.

Security Threats and Mitigation

Remote monitoring systems are susceptible to various security threats that require appropriate mitigation strategies.

- Denial-of-Service (DoS) Attacks: These attacks aim to overwhelm the system with traffic, making it unavailable. Mitigation strategies include implementing rate limiting, using DDoS protection services, and having redundancy in place.

- Man-in-the-Middle (MitM) Attacks: Attackers intercept communication between the system and the user, gaining access to sensitive data. Using strong encryption and verifying certificates can prevent such attacks.

- Data Exfiltration: Attackers attempt to steal data from the system. Strong access controls, data encryption, and regular monitoring can help prevent data exfiltration.

- Malware and Viruses: Malicious software can infect the system, compromising its security and functionality. Regularly updating antivirus software, implementing a secure software development lifecycle, and restricting user access to untrusted sources can mitigate this threat.

Importance of Security in Asset Remote Monitoring

Implementing robust security measures is crucial for several reasons:

- Data Protection: Protecting sensitive data about assets from unauthorized access and misuse is essential for maintaining confidentiality and privacy.

- System Reliability: Ensuring the reliability of the remote monitoring system is crucial for continuous operation and avoiding disruptions.

- Operational Continuity: Maintaining operational continuity is critical for preventing downtime and ensuring the smooth functioning of assets.

- Compliance: Adhering to industry regulations and compliance standards regarding data security and privacy is essential for avoiding legal penalties and reputational damage.

Cost and ROI of Asset Remote Monitoring

Implementing asset remote monitoring systems can be a significant investment, but the potential return on investment (ROI) can be substantial. By gaining real-time insights into asset health and performance, organizations can optimize maintenance schedules, reduce downtime, and extend asset lifecycles, ultimately leading to significant cost savings and improved operational efficiency.

Cost Factors Associated with Asset Remote Monitoring

The cost of implementing an asset remote monitoring system can vary depending on several factors, including the type and complexity of the system, the number of assets being monitored, and the level of integration required.

- Hardware Costs: This includes the cost of sensors, gateways, and communication infrastructure. The choice of hardware will depend on the specific requirements of the monitoring system, such as the type of data being collected, the range of the sensors, and the communication protocol used.

- Software Costs: Software costs include the cost of the monitoring platform, data analytics software, and any custom applications developed for specific monitoring requirements. The choice of software will depend on the desired features, such as data visualization, alarm management, and reporting capabilities.

- Installation and Integration Costs: This includes the cost of installing sensors, configuring the system, and integrating it with existing systems. The complexity of the installation and integration process will depend on the size and complexity of the system.

- Maintenance Costs: Ongoing maintenance costs include the cost of replacing sensors, updating software, and providing technical support. The frequency and cost of maintenance will depend on the reliability of the hardware and software, as well as the level of support required.

Potential Return on Investment (ROI)

The ROI of asset remote monitoring can be measured in several ways, including:

- Reduced Downtime: By identifying potential issues before they become critical, asset remote monitoring can significantly reduce downtime. This can be particularly beneficial for critical assets, such as production equipment or infrastructure systems, where downtime can be costly. For example, a manufacturing company using remote monitoring to track the performance of its machines might be able to identify and address a potential bearing failure before it causes a major breakdown, saving thousands of dollars in lost production time and repair costs.

- Optimized Maintenance Schedules: Asset remote monitoring provides real-time data on asset performance, allowing organizations to schedule maintenance based on actual usage and condition, rather than on fixed schedules. This can help to extend asset lifecycles, reduce maintenance costs, and improve overall efficiency. For instance, a fleet management company using remote monitoring to track the performance of its vehicles might be able to identify and address minor issues before they escalate into major repairs, reducing maintenance costs and extending the lifespan of the vehicles.

- Improved Asset Utilization: Asset remote monitoring can provide insights into asset usage patterns, allowing organizations to optimize asset utilization and reduce idle time. For example, a construction company using remote monitoring to track the location and usage of its equipment might be able to identify underutilized assets and redeploy them to more productive tasks, improving overall efficiency.

- Increased Safety: Asset remote monitoring can help to improve safety by providing early warning of potential hazards, such as equipment malfunctions or environmental changes. For example, a mining company using remote monitoring to track the performance of its equipment might be able to identify and address a potential safety hazard before it causes an accident, reducing the risk of injuries and fatalities.

Examples of Cost Savings and Efficiency Improvements

- Manufacturing: A manufacturing company using remote monitoring to track the performance of its machines might be able to identify and address a potential bearing failure before it causes a major breakdown, saving thousands of dollars in lost production time and repair costs.

- Fleet Management: A fleet management company using remote monitoring to track the performance of its vehicles might be able to identify and address minor issues before they escalate into major repairs, reducing maintenance costs and extending the lifespan of the vehicles.

- Energy: An energy company using remote monitoring to track the performance of its wind turbines might be able to identify and address issues that are affecting turbine efficiency, reducing energy loss and increasing revenue.

Final Wrap-Up

In the end, asset remote monitoring represents a significant shift in the way businesses manage their assets. It allows for proactive decision-making, reducing downtime and maximizing asset lifespan. By embracing the potential of remote monitoring, organizations can unlock a wealth of benefits, paving the way for a more efficient, sustainable, and profitable future.

Asset remote monitoring offers a powerful way to track the health and location of your assets in real-time. For visualizing and analyzing this data, you can leverage the capabilities of qgis , a powerful open-source geographic information system. With qgis, you can create interactive maps that display asset locations, performance metrics, and other critical information, enabling you to make informed decisions about maintenance, deployment, and resource allocation.