Abaqus is a robust and widely used finite element analysis (FEA) software package that empowers engineers and scientists to simulate and analyze complex physical phenomena. It provides a comprehensive suite of tools for modeling, solving, and interpreting results, making it a valuable asset for various engineering disciplines.

Table of Contents

From structural analysis to material modeling and dynamic simulations, Abaqus offers a rich set of capabilities to tackle intricate engineering challenges. Its foundation lies in the powerful finite element method, which allows for the discretization of complex geometries into smaller elements, enabling the numerical solution of partial differential equations that govern physical behavior.

Introduction to Abaqus

Abaqus is a powerful and widely used finite element analysis (FEA) software package that plays a crucial role in engineering and scientific analysis. It provides a comprehensive suite of tools for simulating the behavior of complex systems under various conditions, enabling engineers and researchers to predict their performance and optimize their designs.

Abaqus is renowned for its versatility and ability to handle a wide range of engineering problems, including structural analysis, heat transfer, fluid flow, and acoustics. It is widely employed in various industries, including aerospace, automotive, manufacturing, and civil engineering, to solve real-world problems.

Core Functionalities of Abaqus

Abaqus is built upon the foundation of finite element analysis (FEA), a numerical method that divides a complex system into smaller, simpler elements. This allows for the approximation of continuous physical phenomena using discrete mathematical equations. The software leverages this method to perform various types of analyses, including:

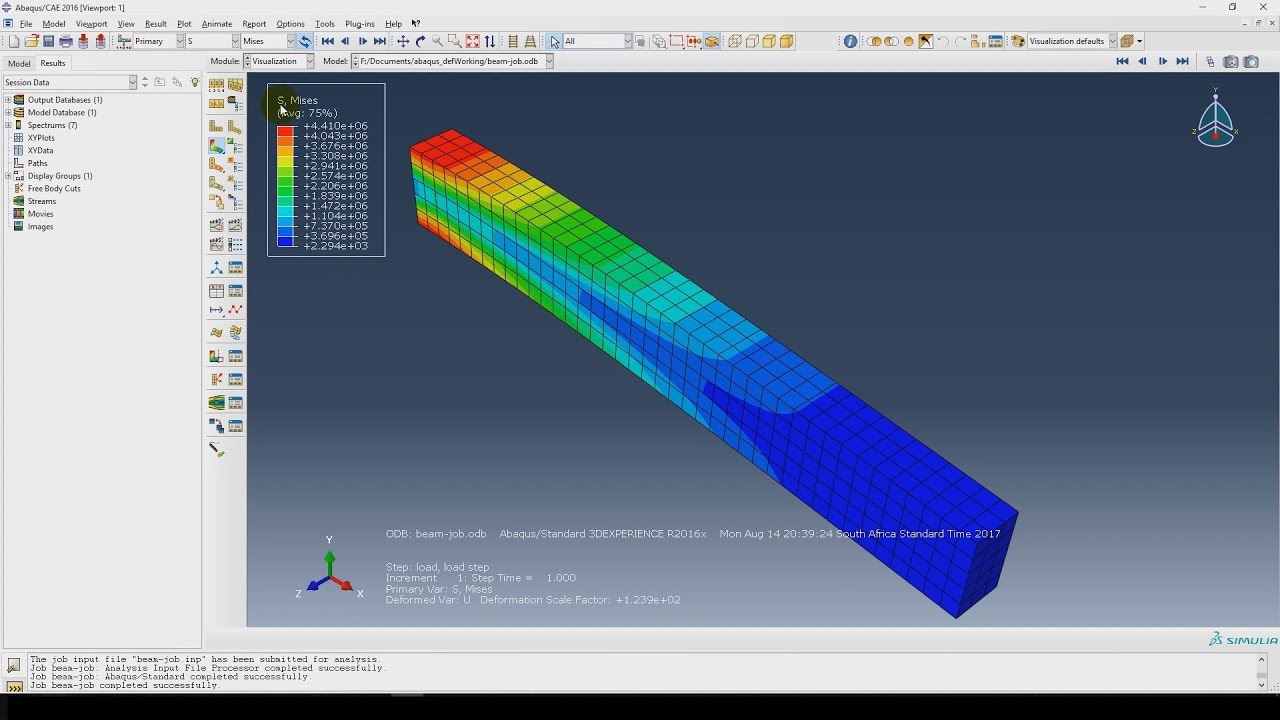

- Structural Analysis: Abaqus enables the analysis of structures subjected to various loads, such as tensile, compressive, bending, and torsional forces. It can predict stress, strain, displacement, and other critical parameters within the structure, helping engineers ensure its structural integrity and safety.

- Heat Transfer Analysis: Abaqus allows the simulation of heat transfer phenomena, including conduction, convection, and radiation. This is crucial for designing systems that effectively manage heat, such as electronic components, engines, and buildings.

- Fluid Flow Analysis: Abaqus provides tools for simulating fluid flow problems, including laminar and turbulent flows. This allows engineers to analyze the behavior of fluids in various applications, such as pipe flow, aerodynamic design, and heat exchangers.

- Material Modeling: Abaqus offers a vast library of material models that accurately represent the mechanical behavior of various materials, including metals, plastics, composites, and concrete. This enables engineers to simulate the material response under different loading conditions and predict its performance.

Advantages of Using Abaqus

Abaqus offers several advantages that make it a preferred choice for engineers and researchers:

- Comprehensive Capabilities: Abaqus provides a comprehensive suite of tools for various engineering analyses, covering structural, thermal, fluid, and acoustic problems. This allows for a unified approach to solving complex multi-physics problems.

- Advanced Material Models: Abaqus boasts a vast library of material models that accurately represent the behavior of various materials, including nonlinear and time-dependent effects. This enables engineers to simulate realistic material responses under complex loading conditions.

- Powerful Pre- and Post-processing Tools: Abaqus offers user-friendly pre- and post-processing tools that facilitate model creation, visualization, and analysis of results. This simplifies the workflow and enhances the user experience.

- Industry-Standard Software: Abaqus is widely used in various industries, making it an industry-standard software. This ensures that engineers can easily share and collaborate on projects, and that results are readily understood and accepted by other professionals.

Limitations of Using Abaqus

Despite its numerous advantages, Abaqus has some limitations that should be considered:

- Complexity and Learning Curve: Abaqus is a complex software with a steep learning curve. Mastering its functionalities requires significant time and effort, especially for beginners.

- Computational Resources: Abaqus simulations can be computationally intensive, requiring significant processing power and memory. This can be a limiting factor for complex models or large-scale simulations.

- Cost: Abaqus is a commercial software package, which can be expensive for individuals or small organizations.

Abaqus Workflow and Methodology

Abaqus is a powerful finite element analysis (FEA) software used for simulating a wide range of engineering problems. Understanding its workflow and methodology is crucial for conducting effective and accurate analyses. This section will delve into the typical steps involved in an Abaqus analysis, highlighting the importance of meshing and discussing the various boundary conditions and loading options available.

Meshing in Abaqus

Meshing is a critical step in any FEA analysis. It involves dividing the geometry of the model into smaller, simpler elements, called finite elements. These elements are then used to approximate the behavior of the actual structure. The quality of the mesh significantly impacts the accuracy and computational efficiency of the analysis.

The choice of mesh density depends on several factors, including the complexity of the geometry, the expected stress gradients, and the desired level of accuracy. A finer mesh, with more elements, provides greater accuracy but also increases computational time. Conversely, a coarser mesh with fewer elements reduces computational time but may sacrifice accuracy.

Boundary Conditions and Loading Options

Boundary conditions define the constraints and supports applied to the model, while loading options represent the external forces or pressures acting on it. Abaqus offers a wide range of boundary conditions and loading options to accurately represent real-world scenarios.

Boundary Conditions

Boundary conditions are essential for defining the constraints of the model. They can be applied to various parts of the geometry, such as edges, faces, or nodes. Some common boundary conditions include:

- Fixed Support: This condition prevents any movement or rotation at the specified location. It simulates a rigid support or a fixed point.

- Symmetry: This condition applies when the model exhibits symmetry, allowing you to analyze only a portion of the structure while taking advantage of the symmetry to reduce computational time.

- Roller Support: This condition allows movement along a specific direction but prevents movement in other directions. It simulates a roller or a slider.

Loading Options

Loading options represent the external forces or pressures acting on the model. They can be applied to various parts of the geometry, such as edges, faces, or nodes. Some common loading options include:

- Force: This option applies a concentrated force at a specific point or along a line.

- Pressure: This option applies a distributed pressure over a surface.

- Temperature: This option applies a temperature load, which can cause thermal expansion or contraction in the model.

Learning Resources and Community

Embarking on your Abaqus journey requires access to a wealth of learning resources and a supportive community. This section delves into the essential resources available to help you master Abaqus and engage with fellow users.

Online Tutorials and Documentation

A comprehensive collection of online resources exists to guide your Abaqus learning. Abaqus documentation, tutorials, and examples are readily available, offering a structured approach to understanding the software’s functionalities.

- Abaqus Documentation: The official Abaqus documentation provides in-depth explanations of every aspect of the software, from basic concepts to advanced techniques. It serves as the primary reference for understanding Abaqus’s capabilities and syntax.

- Simulia Learning: Simulia Learning, the official training platform for Abaqus, offers a range of courses, tutorials, and webinars covering various aspects of Abaqus, from introductory concepts to specialized applications. This platform provides a structured learning path with practical exercises and real-world examples.

- Online Tutorials: Numerous online tutorials and video series are available on platforms like YouTube and Coursera. These resources offer diverse perspectives and approaches to learning Abaqus, catering to different learning styles.

Abaqus User Community and Forums

The Abaqus user community plays a vital role in fostering knowledge sharing and support. Engaging with this community provides a platform to connect with experienced users, seek assistance, and contribute to the collective understanding of Abaqus.

- Simulia Community: The Simulia Community is a dedicated online forum for Abaqus users to exchange knowledge, ask questions, and share experiences. This platform is a valuable resource for troubleshooting issues, seeking guidance on specific applications, and staying updated on the latest developments.

- Abaqus Forums: Numerous online forums, such as the Abaqus forum on Engineering.com, provide a space for users to discuss Abaqus-related topics, share solutions, and collaborate on projects. These forums offer a platform for peer-to-peer learning and support.

Abaqus in Academic Research and Industry Applications

Abaqus is widely used in academic research and industrial applications, making it a valuable tool for engineers, researchers, and scientists. Its versatility and advanced capabilities enable the simulation of complex engineering problems across diverse industries.

- Academic Research: Abaqus is extensively employed in academic research, facilitating the simulation of various phenomena, including structural analysis, fluid dynamics, heat transfer, and material behavior. Researchers utilize Abaqus to validate theoretical models, explore new concepts, and conduct virtual experiments.

- Industry Applications: Abaqus finds applications in various industries, including aerospace, automotive, manufacturing, civil engineering, and biomedical engineering. Engineers leverage Abaqus to design and optimize products, predict performance, and ensure safety, leading to improved efficiency and reduced costs.

Case Studies and Examples

Abaqus has been used in a wide range of industries to solve complex engineering problems. This section will showcase real-world examples of how Abaqus has been used to address engineering challenges, highlighting the successes and challenges encountered.

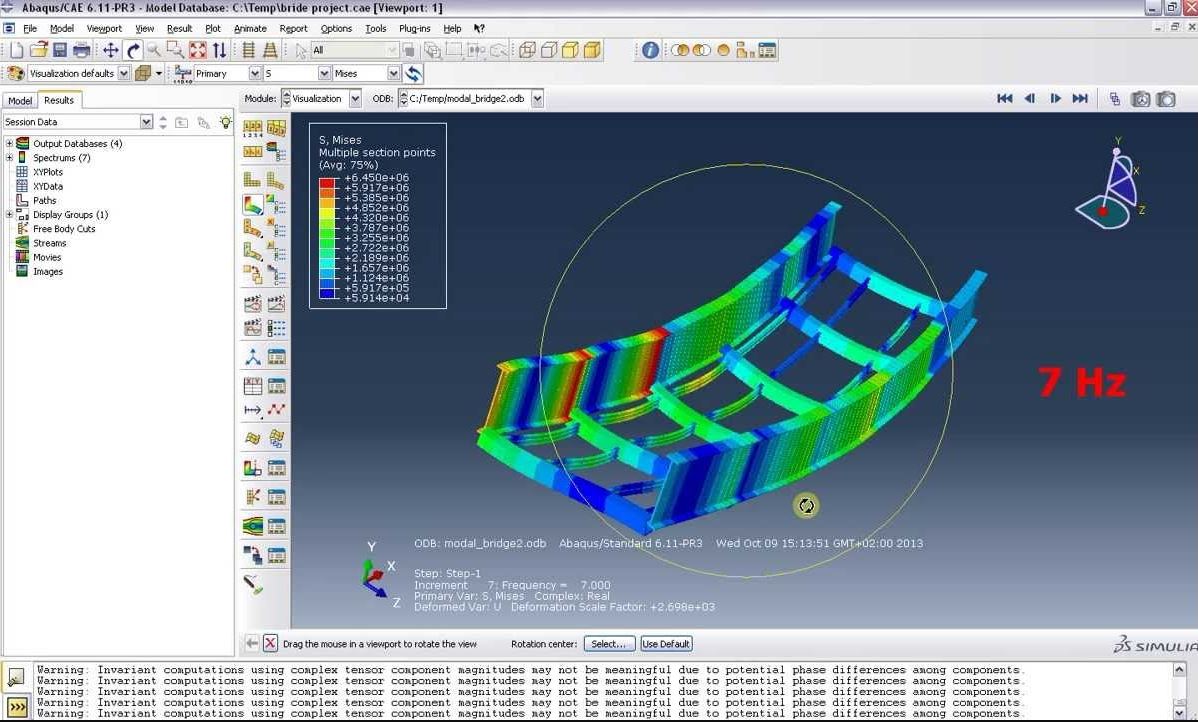

Bridge Design Optimization

This case study focuses on the design optimization of a bridge using Abaqus. The goal was to minimize the weight of the bridge while ensuring its structural integrity.

- Problem: The original bridge design was heavy and expensive. The engineers wanted to find a lighter design that could still withstand the expected loads.

- Solution: Abaqus was used to perform finite element analysis (FEA) on the bridge design. The software allowed the engineers to simulate the bridge’s behavior under different loading conditions. They used this data to optimize the design, reducing the weight of the bridge by 20% while maintaining its structural integrity.

- Outcome: The optimized bridge design was lighter and more cost-effective. This demonstrates how Abaqus can be used to improve the efficiency and cost-effectiveness of engineering projects.

Aircraft Wing Stress Analysis

This case study involves the stress analysis of an aircraft wing using Abaqus. The objective was to determine the stress distribution in the wing under different flight conditions.

- Problem: Aircraft wings are subjected to complex stress patterns during flight. It is essential to understand these stress patterns to ensure the structural integrity of the wing.

- Solution: Abaqus was used to perform FEA on the aircraft wing. The software allowed the engineers to simulate the wing’s behavior under various flight conditions, including take-off, landing, and cruising. The analysis revealed the stress distribution in the wing under different flight conditions.

- Outcome: The analysis provided valuable insights into the stress distribution in the aircraft wing. This information was used to optimize the wing design and ensure its structural integrity.

Crash Simulation

This case study explores the use of Abaqus in crash simulation to analyze the impact of a vehicle collision. The goal was to understand the deformation and damage patterns in the vehicle during a crash.

- Problem: Vehicle crashes are complex events that involve significant forces and deformation. It is important to understand the impact of these forces on the vehicle’s structure.

- Solution: Abaqus was used to perform crash simulation. The software allowed the engineers to simulate the vehicle’s behavior during a collision. The simulation provided detailed information about the deformation and damage patterns in the vehicle.

- Outcome: The crash simulation results were used to improve the safety of the vehicle design. The analysis identified areas of weakness in the vehicle’s structure and provided guidance for redesigning the vehicle to minimize the risk of injury during a crash.

Piping System Analysis

This case study focuses on the analysis of a piping system using Abaqus. The objective was to determine the stresses and strains in the piping system under different operating conditions.

- Problem: Piping systems are often subjected to high pressures and temperatures. It is essential to ensure the structural integrity of the piping system to prevent leaks and failures.

- Solution: Abaqus was used to perform FEA on the piping system. The software allowed the engineers to simulate the system’s behavior under various operating conditions, including pressure changes and temperature fluctuations. The analysis revealed the stresses and strains in the piping system.

- Outcome: The analysis provided valuable insights into the stresses and strains in the piping system. This information was used to optimize the design of the piping system and ensure its structural integrity.

Comparison with Other FEA Software: Abaqus

Choosing the right FEA software is crucial for any engineering project. Each software package comes with its unique strengths and weaknesses, making it essential to consider your specific needs and project requirements. This section will compare Abaqus with other popular FEA software packages like ANSYS, COMSOL, and Nastran, highlighting their key features, capabilities, and usability.

Strengths and Weaknesses of Different FEA Software

This section explores the strengths and weaknesses of Abaqus, ANSYS, COMSOL, and Nastran, focusing on their key features, capabilities, and usability.

- Abaqus is known for its comprehensive capabilities in nonlinear analysis, advanced material models, and complex contact simulations. It excels in simulating large deformations, fracture mechanics, and complex material behavior, making it ideal for applications like metal forming, crashworthiness analysis, and biomechanics. However, its steep learning curve and complex user interface can be challenging for beginners.

- ANSYS offers a wide range of analysis capabilities, including structural, thermal, fluid, and electromagnetic analysis. It boasts a user-friendly interface and extensive documentation, making it popular for both beginners and experienced users. However, its pricing can be expensive, and its focus on broad applications might lack the depth and specialized features found in Abaqus for specific engineering problems.

- COMSOL excels in multiphysics simulations, allowing users to model and analyze the interaction of different physical phenomena, such as fluid flow, heat transfer, and structural mechanics. Its intuitive graphical user interface and comprehensive documentation make it suitable for various applications, including microfluidics, MEMS, and bioengineering. However, its focus on multiphysics can make it less specialized for specific engineering disciplines compared to Abaqus or ANSYS.

- Nastran is a widely used FEA solver known for its robustness and accuracy in linear analysis. It is often used in aerospace and automotive industries for structural analysis, vibration analysis, and fatigue analysis. However, its limited capabilities in nonlinear analysis and complex material models might not be suitable for all applications.

Use Cases Where Abaqus Might Be Preferred

Abaqus stands out in specific engineering scenarios due to its advanced capabilities in nonlinear analysis and complex material modeling. Here are some examples:

- Metal forming simulations: Abaqus’s capabilities in large deformation analysis, contact mechanics, and advanced material models are crucial for accurately simulating metal forming processes like forging, extrusion, and rolling.

- Crashworthiness analysis: Abaqus’s ability to handle large deformations, material failure, and contact interactions makes it ideal for simulating vehicle crashes and other impact events.

- Biomechanics: Abaqus’s advanced material models and capabilities in simulating complex biological tissues and structures make it suitable for applications in biomechanics, such as bone fracture analysis, soft tissue modeling, and implant design.

- Fracture mechanics: Abaqus excels in simulating crack propagation and fracture behavior, making it suitable for applications like fatigue analysis, stress corrosion cracking, and damage mechanics.

Final Thoughts

Abaqus stands as a testament to the power of numerical analysis and its transformative impact on engineering design and decision-making. Its versatility, coupled with its user-friendly interface and comprehensive documentation, makes it a compelling choice for both novice and seasoned engineers. As the field of engineering continues to evolve, Abaqus will undoubtedly play a pivotal role in pushing the boundaries of innovation and driving progress in diverse industries.

Abaqus is a powerful finite element analysis software widely used in engineering, allowing for complex simulations and analysis. When it comes to ensuring the integrity of your Abaqus data and project files, a robust backup solution like Macrium Reflect can provide peace of mind.

This software’s image-based backups can capture your entire system, including Abaqus installations and project files, ensuring a quick and reliable recovery in case of unexpected issues.